While Sino-US trade conflict continues to affect global markets and business confidence, multinational companies have been adjusting their business strategies. According to a survey by Bain & Company, 50% of American corporates went into a wait-and-see mode last year amid uncertainties, but 60% are ready to take action this year1. Should China be worried that manufacturing production will move away?

Low end manufacturing has been moving from Pearl River Delta and Yangtze River Delta regions to lower-cost Southeast Asia for quite a number of years, as Chinese workers’ wages keep rising and the government is determined to reduce pollution. In order to transform China into an advanced global manufacturing economy, the country has been changing its manufacturing strategy and devised a ten year plan to move up the value chain. Admittedly, China carries some fundamental weaknesses in core technology independence, such as semiconductors; however, China’s strength lies in its manufacturing capability. With traditional low cost value proposition and its focus and development of innovation to develop advanced technologies in manufacturing, China was ranked as the most competitive manufacturing nation in 20162. Many of world’s most popular electronics are assembled in China, with high-tech exports increasing from 24,639 million USD in 1998 to 504,380 million USD in 20173. Germany and Japan also excel in producing quality hi-tech products; however, their shrinking and aging workforce and high cost make it more difficult to deliver customized products with mass production efficiency.

Infrastructure is critical to building a strong manufacturing supply chain. We need fundamental facilities and systems to serve an industrial cluster, such as roads, bridges, ports, water supply, sewers, electrical grids, and telecommunications. An efficient and complete supply chain which can produce quality products in massive supply requires not only solid infrastructure, but raw material supply, such as labor and industry cluster. Can Southeast Asia, India or Mexico easily copy a supply chain ecosystem in the near future? To answer this question, we can think about the following four factors.

Capital

China has been investing billions of dollars in building the supply chain infrastructure during the forty years of reform and opening up so that it has successfully nurtured thousands of industrial clusters, varying from textile manufacturing to high-end industrial robot production. Infrastructure systems require large-scale construction, which involves capital-intensive financing. It’s possible to build and operate scattered factories in developing countries for multinational companies, but raising capital to finance nationwide infrastructure projects that can facilitate versatile supply chains is a big challenge.

Talent

Talent and labor force is the most important driver of a country’s manufacturing ability to compete on the global stage. First, an economy needs a stable supply of construction workers to build infrastructure efficiently, but most countries are facing manpower shortage as very few young people would consider a career in the construction industry. Second, high end manufacturing requires skilled workers to fill critical positions, such as machine/equipment operators and automation supervisors, and this talent pool may take years of education and training to develop. Most developing countries face challenges in addressing the skills gap and attracting talents to relocate to their local plants.

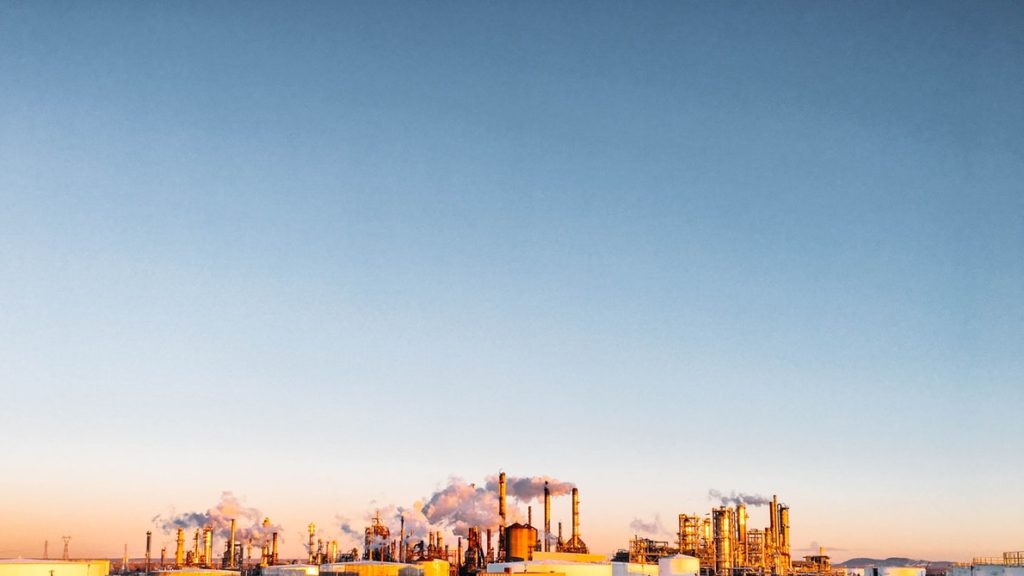

Pollution

Besides the Great Wall, the first thing foreign travelers hear about Beijing might be the air pollution. Expats even coined the term “Beijing Cough” to describe a bout of persistent dry cough or throat tickle caused by poor air quality. China’s rapid manufacturing expansion comes at the expense of the environment and the government has been very determined about fighting pollution in recent years, even being willing to tolerate slower economic growth. Many Southeast Asian countries’ economic growths rely heavily on tourism and some ecosystems are already under threat of over-exploitation. Nowadays, how many countries are willing to sacrifice the environment to pursue fast industrial development?

Time

Last but not least, building a sustainable supply chain takes a long time. China took decades to build infrastructure, train skilled workers, and nurture industrial clusters. Even if there were enough capital and talents, countries still need many years to develop their manufacturing capability without devastating the environment.

On May 20, the US footwear industry, including the Top 2 Sports brands in the world – Nike and Adidas, sent an open letter to the White House and urged the Trump Administration to consider a halt in raising tariffs on footwear imported from China, saying that a 25% tariff “will add $7 billion in additional costs for our customers, every single year.”4 Facing trade protectionism in different regions, shoe companies have been working on addressing trade issues and preparing to reduce the impact in recent years. Many have been shifting part of production out of China to save cost and reduce reliance on a single country. For fiscal year 2018, China manufactured approximately 26% of total NIKE brand footwear and 26% of total NIKE Brand apparel, compared with 47% and 18% from Vietnam, respectively5. Puma sourced 24% of its products from China, while Vietnam contributed 32%4. But still, China represents an important sourcing country and consumer market for global footwear and apparel industry. As said in the letter, companies cannot simply move factories to adjust to these changes since they need to make sourcing decisions years in advance.

When moving factories out of China, multinationals need to take a lot of factors into consideration, such as the costs of relocation, labor market (not only cost, but also size and skills of labor force), physical infrastructure, supplier network, legal and tax system, political stability, supporting industries, etc. Certainly, a country’s manufacturing competitiveness level may vary from industry to industry, but China still has competitive advantages in high-end mass production.

[1] Source: CNBC, as of April 2019

[2] Source: Deloitte, as of March 2016; Deloitte Touche Tohmatsu Limited and US Council on Competitiveness, 2016 Global Manufacturing Competitiveness Index

[3] Source: Knoema, as of Dec 2017

[4] Source: Bloomberg, as of May 2019

[5] Source: NIKE Annual Report, as of May 2018

Disclaimer

This document is based on management forecasts and reflects prevailing conditions and our views as of this date, all of which are accordingly subject to change. In preparing this document, we have relied upon and assumed without independent verification, the accuracy and completeness of all information available from public sources. All opinions or estimates contained in this document are entirely Zeal Asset Management Limited’s judgment as of the date of this document and are subject to change without notice.

Investments involve risks. Past performance is not indicative of future performance. You may lose part or all of your investment. You should not make an investment decision solely based on this information. Each Fund may have different underlying investments and be exposed to a number of different risk, prior to investing, please read the offering documents of the respective funds for details, including risk factors. If you have any queries, please contact your financial advisor and seek professional advice. This material is issued by Zeal Asset Management Limited and has not been reviewed by the Securities and Futures Commission in Hong Kong.

There can be no assurance that any estimates of future performance of any industry, security or security class discussed in this presentation can be achieved. The portfolio may or may not have current investments in the industry, security or security class discussed. Any reference or inference to a specific industry or company listed herein does not constitute a recommendation to buy, sell, or hold securities of such industry or company. Please be advised that any estimates of future performance of any industry, security or security class discussed are subject to change at any time and are current as of the date of this presentation only. Targets are objectives only and should not be construed as providing any assurance or guarantee as to the results that may be realized in the future from investments in any industry, asset or asset class described herein.